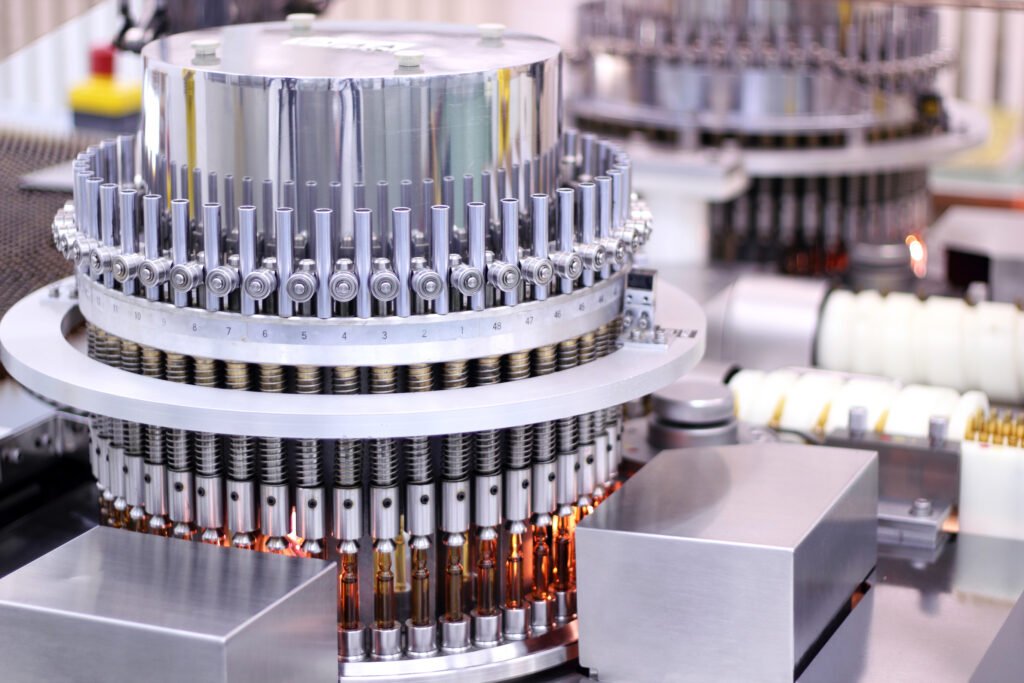

In the world of pharmaceutical and biotech manufacturing, quality is non-negotiable. Whether a drug is taken orally, applied topically, or administered via injection, patients trust that it is safe, effective, and consistently produced. At the heart of ensuring that trust are two key standards: Good Manufacturing Practices (GMP) and Current Good Manufacturing Practices (cGMP). Although they sound similar, they are not the same. Understanding the distinction is essential for both industry professionals and informed consumers.

What Is GMP?

GMP stands for Good Manufacturing Practices. These are a set of minimum standards that pharmaceutical manufacturers must follow to ensure that products are consistently high in quality. Developed by agencies like the U.S. Food and Drug Administration (FDA), European Medicines Agency (EMA), and World Health Organization (WHO), GMPs cover everything from equipment maintenance to personnel training and sanitation.

Key GMP principles include:

- Clean and hygienic manufacturing areas

- Validated processes and equipment

- Detailed documentation and traceability

- Routine quality testing of products

These practices are required to prevent errors and contamination, ensuring that drug products are safe for human use.

What Is cGMP?

The “c” in cGMP stands for “current.” It signals the requirement for manufacturers to stay up to date with the latest science, technology, and risk management practices. The U.S. FDA emphasizes that cGMP regulations not only require basic compliance, but also continuous improvement through:

- Real-time monitoring systems

- Updated quality management frameworks

- Staff training on emerging technologies

- Adoption of new manufacturing equipment and digital tools

The FDA defines cGMP as a dynamic, evolving set of standards that ensure proactive quality assurance across the product life cycle.

According to the FDA:

“The ‘current’ in cGMP reminds manufacturers that they must employ technologies and systems that are up to date in order to comply with the regulations.“

— U.S. FDA, cGMP Overview

GMP vs. cGMP: A Side-by-Side Comparison

| Feature | GMP | cGMP |

|---|---|---|

| Definition | Foundational manufacturing standards | Updated standards incorporating latest best practices |

| Technology Requirement | Basic or traditional processes acceptable | Requires use of modern technology |

| Flexibility | Allows discretion in implementation | Requires active improvement and adaptation |

| Cost Implication | Generally more cost-efficient | Requires higher investment in tech and training |

| Regulatory Rigor | Standard audits and validations | Deeper inspections and higher expectations |

Why Strive for cGMP Compliance?

While cGMP compliance may seem resource-intensive, it’s a strategic investment with clear returns:

- Fewer deviations and batch failures

- Improved product consistency

- Stronger position during regulatory inspections

- Increased global market competitiveness

Pharmaceutical manufacturers pursuing cGMP can also demonstrate regulatory leadership, which is especially important in highly competitive and globalized markets.

Conclusion: Setting a Higher Bar

In summary, GMP is your baseline. cGMP is your gold standard.

If you’re a manufacturer, aiming for cGMP isn’t just a matter of compliance—it’s an investment in quality, reputation, and long-term success. If you’re a consumer or health professional, understanding these standards empowers you to trust the systems that safeguard product quality.

Because when it comes to health, “good enough” simply isn’t enough.

References

- “The ‘current’ in cGMP reminds manufacturers that they must employ technologies and systems that are up to date in order to comply with the regulations.“

— U.S. FDA, cGMP Overview